Did you know the the NFPA (National Fire Protection Association) recommends annual infrared surveys for electrical systems? Many insurance carriers are now requiring electrical surveys be completed to satisfy coverage requirements. Adam Lask of Lask Inspection Group, LLC, is an Infraspection Level 3 certified thermographer #13497, and can help you with your surveys. We save our clients thousands of dollars in avoiding costly repairs and minimizing downtimes.

What is an Infrared Survey?

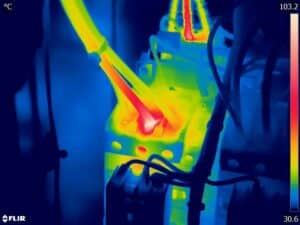

Our infrared surveys are conducted to identify problems in an electrical system (and other applications). Heat is generated through electrical current and thermal detectors are used to detect this heat. We find specific thermal signatures of issues in your electrical system. Issues include: Poor/Loose Connections, Unbalanced Loads, Faulty Equipment, and Overloaded Circuits.

- Surveys are completed quickly

- No equipment shut down is necessary

Actually, equipment must be operating for infrared surveys to detect thermal anomalies. In the photo above, an IR image shows a connection issue at a contactor. Visual inspection alone shows no issues to be concerned about. Professional thermographers identify these issues before equipment is damaged and production is halted.

Benefits of an Infrared Survey

Benefits of these surveys include the following (not in any particular order):

- Avoid Costly Downtime

- Increase Efficiency

- Avoid Unnecessary Repairs

- Avoid Losses In Production

- Avoid Catastrophic/Dangerous Failures

- Increase Safety

- Increase Equipment Life

Equipment to check for Infrared Surveys

We scan the following equipment:

- Automatic Transfer Switches

- Transformers

- Motor Control Centers

- Switchgear

- Lighting Panels

- Distribution Panels

- Control Panels

- Disconnects

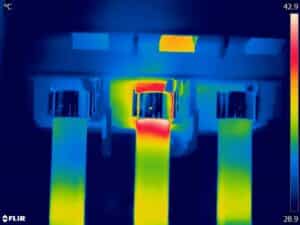

We have found various thermal anomalies in our surveys. It’s important to view the interior of equipment to check these connections. Qualified personnel are a must in these surveys.

How Lask Inspection Group can Help

We provide actionable advice to our clients through professional reports while using professional equipment. Our equipment is professional grade. The image below shows equipment used by untrained inspectors.

Our reports include a cost savings reports based off insurance statistics to help show our clients the financial benefits of infrared surveys. In some cases, clients save money through a reduction in insurance premiums. Our surveys provide a very high return on investment and will benefit your operations year after year.

Additional Applications

Lask Inspection Group, LLC offers additional uses of this technology. Motor trending is popular to help predict when motors may fail. Motor trending involves more frequent inspection of critical equipment. Our clients can prepare for motor replacement at specific temperature thresholds or through qualitative analysis. Other clients prefer building envelope scanning. Building envelope issues include moisture intrusion in walls and low slope roof assemblies, insulation deficiencies, energy loss through air leakage, and other applications. Call our office to discuss how we can help you save money and provide a more productive and efficient workplace. We service the Midwest states for this service, including Illinois, Wisconsin, Minnesota, Iowa, Indiana, Ohio, Missouri, and Kentucky.